-

Q-Pumps

q-pumps

-

QTS SANITARY TWIN SCREW PUMPS

Q-Pumps QTS Series Pumps

QTS twin screw (spindle) pumps are an innovative new positive displacement sanitary process solution. QTS pumps eliminate many problems common to other types of positive displacement pumps. They have low NPSH requirements while being able to self-prime bi-directionally. These twin screw pumps operate very quietly, even at high speed. They also have no axial deflection unlike rotary lobe pumps or centrifugal models. This reduces the amount of wear and tear on seals, the gear case and the shafts themselves which means less time and money spent on maintenance and repair parts. Furthermore, QTS Pumps can be used as a process pump and CIP pump in the same system while taking less time for a CIP cycle than progressing cavity pumps. QTS pumps offer many more features and benefits!- Very Soft Solids Handled without Damage Up to Max Solid Size 1.5"" With Improved Surfaces for Abrasive Fluids

- Low Shear- Fluid Travels along Rotor Axis, Reducing Fluid Speed

- Virtually Pulse-Free, Constant Flow

- Bi-directional Pumping, Self-Priming in BOTH Directions

- Totally Drainable, 100% CIP-able Running at High Speeds

- Ideal to be Used as Process Pump as Well as a CIP Pump: Removing the Cost of Additional Equipment

- Low NPSH Requirement due to the High Suction Capacity

- Meets 3-A & EHEDG Standards

- Optimized Engineered Rotor Design, No-Contact Even At High Pressure

Q-Pumps QTS Twin Screw Pump Demonstration Video

Q-Pumps QTS Applications Video -

QC / QC+ / IC+ SERIES CENTRIFUGAL PUMPS

At Q-Pumps we have developed this technology to ease the assembly of centrifugal pumps The QC+ Series is ideal for sanitary and non-sanitary applications such as the food, beverages, and agriculture industries. With many upgrading options available, we are sure our pump will work as if it was tailor-made. Certifications: 3A

Characteristics- Manufactured under the NEMA or IEC norms.

- Stainless steel 316L for the parts in contact with the product

- Open Impeller

- Can work in 50 and 60 Hz

- Stainless steel 304 adapter

- Clamp connections: Bridas, Bevel Seat and DIN

QC+- Eases and speeds up the QC series pumps assembly

- Better impeller support with a wedge and a nut

- Greater long-term efficiency

Reference Data- Flow: 1,200 gpm / 4,542 lpm

- Pressure: 117 psi / 8 bar

- Viscosity: 600 cP

- Temperature: 120ºC / 248ºF

-

QP SERIES CIRCUMFERENTIAL PISTON PUMPS

Circumferential piston pumps, interchangeable with other brands

Say goodbye to expensive spare parts

The QP Series is characterized by being Universally interchangeable with other brands in the market, even improving the quality of the spare parts. Certificates: 3A, EHEDG

Characteristics- 304 stainless steel seals

- Helical gears

- Flexibility for 4 mounting positions

- Grease fittings on both sides

- Antimicrobial lubricant

- Alloy 88 rotors

- 6 threaded oil plugs with glass peepholes

- Self-cleaning packages in the plugs.

- Gearbox made of stainless steel, which makes it more resistant than conventional cast-iron gearboxes

- The oil-seal is made of stainless steel which prevents oxidation

- High-torque shafts made of one alloy makes them more resistant

- Self-cleaning gaskets

- 100% interchangeable and compatible with other series in the market

- QP1 and QP2 models can be reconstructed using larger rotors to extend the life of the equipment

- Remanufacturing program*: Reconditioned pumps with a one-year warranty.

- Flow: 312 gmp / 1,181 gpm

- Pressure: 31bar / 450psi

- Viscosity: 1,000,000 cps

- Temperature: 204ºC / 400ºF

-

QL SERIES LOBE PUMPS

Lobular pumps at a great price

Lobular pumps for great performance

The QL Series feature positive displacement and due to their great versatility, can be adjusted to different applications. Certifications: 3A and EHEDG

Characteristics

- Has 4 different seal types to match each application

- Standard seal material: Tungsten Carbide vs. Tungsten Carbide

- Connections: Clamp (standard), SMS, Bevel Seat, DIN, and Brida available

- Different rotor options: Bi-wing, Single-wing, Tri-lobe, Multi-lobe

- Bearing box available in cast iron or stainless steel

Advantages- Accessible price

- The front access allows quick and easy cleaning

- The bi-wing rotors geothermic design offers a very high performance

- Thanks to the pumps versatility, it can be tailored to meet each application need

- Flow: 441 gpm / 1,670 lpm

- Pressure: 20 bar / 300 psi

- Viscosity: 1,000,000 cP

- Temperature: 149ºC / 300ºF

-

QIS SERIES CENTRIFUGAL PUMPS

Completely redesigned 100% electropolished centrifugal pump with an internal seal

This new sanitary series is ideal for sanitary and non-sanitary applications, perfect for the food & beverage and pharmaceutical industries. Designed under 3-A & EHEDG standards.

Characteristics- 100% Electropolished

- Internal seal on all models (single and double)

- With a new back cover

- Energy saving

- More hygienic pump

- Fully drainable

- Semi-open impeller

- Greater efficiency

- Volute casing

- Up to 800 cP

- Design that complies 3A and EHEDG standards

- Same footprint of a QC+ Pump

QIS Pump is 100% electropolished, which reduces its surfaces roughness, and improves its finish

Electropolished process is essential in the food, medical and pharmaceutical industries due to its optimum hygienic conditions that prevents bacteria deposits from forming

- Hygienic surface that prevents bacteria

- Creates a clean, smooth surface that is easier to sterilize

- Improves corrosion resistance

- Polish areas that are inaccessible by other polishing methods

- Sterilize workpieces

Reference Data:

800 cP -

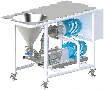

QDU SERIES DRUM UNLOADERS

The most efficient and hygienic Drum Unloader in the market

The fastest Drum Unloader with the less energy consumption

Save energy while increasing efficiency. QDU Series is a Drum unloader equipment, fully designed with an integrated QTS twin screw pump link up to an electric motor, which allows a saving energy consumption.

Characteristics- Constant flow

- It’s hygienic design integrates an EHEDG certified QTS Pump

- Can handle viscosities from 1 to 1,000,000 cP

- Accurate metering

- Up to 360 psi

- Energy saving due the use of efficient electric motors

- Deliver faster unloading

- Electric Drum QTS pump provides a substantial increase in efficiency over less efficient air-operated pump

- Quieter operation

- Pressure: 25 bar / 360 psi

- Viscosity: From 1 to 1,000,000 cP

-

QIM Sanitary Mixers

The most versatile mixers in the market.

Perfectly created solutions for applications that require to be homogenized or disintegrated while being pumped. Centrifugal equipment in radial flow line designed under 3-A & EHEDG standards.

CHARACTERISTICS

- Has a semi-open impeller design to keep pressurized and achieve better lubrication in the mechanical seal.

- Built in SS 316L with surface finish on all surfaces in contact with the fluid 32 Ra maximum

- Completely drainable with the discharge in horizontal position

- Use of o-ring to achieve a better seal

- Easy maintenance and high efficiency

- 5 different backplates options for better performance

- Designed under 3-A and EHEDG standards

BACKPLATE OPTIONS

- Big Slots: For disintegrations of hard solids

- Big Inclined Slots: For disintegration of small solids

- Big Radial Slots: For mixing powders and liquids

- Small Slots: For disintegrations of soft solids

- Small Radial Slots: For emulsifying different liquids

ADVANTAGES

- Thanks to its modular design, QIM Inline Mixers can be converted into a QDB Dry Blender by adding a table and a cone

- It’s different backplate options makes the QIM tailor-made for each application

- A QC+ can be converted into a QIM

- Reference Data

- Flow: 352 gpm / 1,333 lpm

- Pressure: 6 bar / 92 psi

- Viscosity: 600 cP

- Temperature: 10º to 150ºC / 14º to 302ºF

Available sizes

QIM 114, QIM 216, QIM 328 -

QDB SERIES MIXERS

The most versatile mixers in the market.

Perfectly created solutions for applications that require to be homogenized or disintegrated while being pumped. Centrifugal equipment in radial flow line designed under 3-A & EHEDG standards.

CHARACTERISTICS

- Has a semi-open impeller design to keep pressurized and achieve better lubrication in the mechanical seal.

- Built in SS 316L with surface finish on all surfaces in contact with the fluid 32 Ra maximum

- Completely drainable with the discharge in horizontal position

- Use of o-ring to achieve a better seal

- Easy maintenance and high efficiency

- 5 different backplates options for better performance

- Designed under 3-A and EHEDG standards

BACKPLATE OPTIONS

- Big Slots: For disintegrations of hard solids

- Big Inclined Slots: For disintegration of small solids

- Big Radial Slots: For mixing powders and liquids

- Small Slots: For disintegrations of soft solids

- Small Radial Slots: For emulsifying different liquids

ADVANTAGES

- Thanks to its modular design, QIM Inline Mixers can be converted into a QDB Dry Blender by adding a table and a cone

- It’s different backplate options makes the QIM tailor-made for each application

- A QC+ can be converted into a QIM

- Reference Data

- Flow: 352 gpm / 1,333 lpm

- Pressure: 6 bar / 92 psi

- Viscosity: 600 cP

- Temperature: 10º to 150ºC / 14º to 302ºF

-

QVM SERIES MIXERS

The most versatile mixers in the market.

Perfectly created solutions for applications that require to be homogenized or disintegrated while being pumped. Centrifugal equipment in radial flow line designed under 3-A & EHEDG standards.

CHARACTERISTICS

- Has a semi-open impeller design to keep pressurized and achieve better lubrication in the mechanical seal.

- Built in SS 316L with surface finish on all surfaces in contact with the fluid 32 Ra maximum

- Completely drainable with the discharge in horizontal position

- Use of o-ring to achieve a better seal

- Easy maintenance and high efficiency

- 5 different backplates options for better performance

- Designed under 3-A and EHEDG standards

BACKPLATE OPTIONS

- Big Slots: For disintegrations of hard solids

- Big Inclined Slots: For disintegration of small solids

- Big Radial Slots: For mixing powders and liquids

- Small Slots: For disintegrations of soft solids

- Small Radial Slots: For emulsifying different liquids

ADVANTAGES

- Thanks to its modular design, QIM Inline Mixers can be converted into a QDB Dry Blender by adding a table and a cone

- It’s different backplate options makes the QIM tailor-made for each application

- A QC+ can be converted into a QIM

- Reference Data

- Flow: 352 gpm / 1,333 lpm

- Pressure: 6 bar / 92 psi

- Viscosity: 600 cP

- Temperature: 10º to 150ºC / 14º to 302ºF

Available sizes

QIM 114, QIM 216, QIM 328