-

UET Mixers

uet-mixers

-

XCEL-2 Series Mixers

Built with large mixer features, the XCEL-2 Series of UET Mixers offers extremely high pumping rates for cost effective, low volume mixing applications such as flash mixing in water treatment and salt dissolving in water. Industrial motors in standard frame sizes, rugged cast iron gearboxes and hardened steel gears, and anti-friction bearings are used in the manufacture of all XCEL-2 Series mixers.

Specifications:

- HP Ratings: Up to 5 HP

- Speed Range: 230 to 1800 rpm

- Motor: NEMA C-face in TEFC

- Gear Drive: High Efficiency helical gears

- Pumping Rates: Up to 7,000 gpm

- Impellor: Hydrofoil for highest efficiency

- Shaft: UP to 96” long without a steady bearing

- Mounting: Baseplate or flange mount

- Compliances: CSA, CE, ATEX, ASME

-

XCEL-3 to XCEL-10 Series Mixers

Each mixer is designed and manufactured for you application using only the highest quality components engineered specifically for dependable mixer service. XCEL-3 to 10 Series mixers are available with pumping rates up to 54,000 gpm and utilize standard industrial motors up to 25 HP.

Specifications:- HP Ratings: Up to 25 HP

- Speed Range: 2 to 350 rpm

- Motor: NEMA C-face in TEFC, XP

- Gear Drive: Worm and helical/worm configurations

- Pumping Rates: Up to 54,000 gpm

- Impellor: Hydrofoil for highest efficiency

- Shaft: UP to 240” long without a steady bearing

- Mounting: Baseplate or flange mount

- Compliances: CSA, CE, ATEX, ASME

-

XCEL-15 to XCEL-22 Series Mixers

XCEL-15 to 22’s are ideal for a wide range of applications where efficiency and dependability are necessary. The gearboxes use high efficiency helical gears, and sport oversized bearings to handle long shafts with high overhung loads for use in applications such as mixing sludge in waste treatment and mixing resin.

Specifications- HP Ratings: Up to 30 HP

- Speed Range: 1 to 400 rpm

- Motor: NEMA C-face in TEFC,XP

- Gear Drive: Helical Gearing Double and triple reduction

- Pumping Rates: Up to 86,000 gpm

- Impellor: Hydrofoil for highest efficiency

- Shaft: UP to 240” long without a steady bearing

- Mounting: Baseplate or flange mount

- Compliances: CSA, CE, ATEX, ASME

-

XCEL-200 to XCEL-220 Series Mixers

XCEL-200 to 220 Series mixers incorporate many of the same construction and operating features, associated with most large capacity mixers, and are ideal for heavy duty mixing applications such as submerged turbine aeration.

A high capacity, spherical roller shaft bearing isolates impellor loads from the gearing, and provides a high moment capacity. Tapered roller bearings accept high thrust loads in either direction.

The rugged cast iron housing is designed to withstand mixing stresses while maintaining accurate gear alignment and resisting corrosion.

Specifications:- HP Ratings: Up to 25 HP

- Speed Range: 2 to 350 rpm

- Motor: NEMA C-face in TEFC, XP

- Gear Drive: Worm and helical/worm configurations

- Pumping Rates: Up to 54,000 gpm

- Impellor: Hydrofoil for highest efficiency

- Shaft: UP to 240” long without a steady bearing

- Mounting: Baseplate or flange mount

- Compliances: CSA, CE, ATEX, ASME

-

XCEL-300 to XCEL-1500 Series Mixers

XCEL-300 to 1500 Series mixers are engineered and manufactured specifically for the demanding operating parameters associated with mixing applications.

Standard designs are available with pumping rates up to 500,000 gpm. These mixers are ideal for chemical and food processing, pulp and paper, and water and waste treatment applications.

The XCEL-300 to 1500 mixers feature gearboxes with fabricated housings and with helical and spiral bevel gear combination. Large diameter output shafts accommodate the high bending moment loads common in difficult mixing applications.

Specifications:- HP Ratings: Up to 1000 HP

- Speed Range: Up to 350 rpm output

- Motor: Foot mounted in TEFC,XP

- Gear Drive: Helical and Bevel gear configurations, double and triple reduction

- Pumping Rates: Up to 500,000 gpm

- Impellor: Hydrofoil for highest efficiency

- Shaft: UP to 50ft. long without a steady bearing

- Mounting: Baseplate or flange mount

- Compliances: CSA, CE, ATEX, ASME

-

XCELight Portable Series Clamp Mount Mixers

Like all UET mixers, the XCELight Portable Mixer is built to last and designed to handle tough mixing applications such as lime make down and polymer storage.

Industrial motors in standard NEMA frames, hardened steel gears, and anti-friction bearings are all standard components used in the manufacture of the XCELight Portable Mixers.

Specifications- HP Ratings: Up to 5 HP

- Speed Range: 230 to 1800 rpm output

- Motor: NEMA C face in TEFC,XP

- Gear Drive: High efficiency helical gears

- Pumping Rates: Up to 7,000 gpm

- Impellor: Hydrofoil for highest efficiency

- Shaft: UP to 90” long

- Mounting: Adjustable C-clamp or saddle plate

- Compliances: CSA, CE, ATEX, ASME

-

Side Entry Mixers

UET side entering mixers are designed and built in the same manner as our top entering mixers. They are commonly used in petroleum, and pulp & paper applications. Industrial motors and mechanical seals are used with rugged cast iron gearboxes featuring oversized tapered roller bearing to carry horizontal shafts.

-

PL Series Pipeline Mechanical Mixers

UET mechanical pipeline mixers meet the need for blending of miscible liquids, dispersion of immiscible liquids, gas contacting, and similar applications.

Pipeline mixers are designed for continuous processing of almost any material. The fluids are brought together within a high turbulence zone where they are mixed intensely. Pipeline Mixers are available in a wide range of configurations and materials, and can be mounted at any angle to meet process requirements.

Specifications- Line Size: Up to 24” dia. Pipe housing

- Hp Rating: Up to 20 Hp

- Mounting: ANSI flanged ends

- Speed Range: 350 rpm to 3600 rpm

- Motor: NEMA C-face

- Impellor: Axial or Radial

- Viscosities: Up to 10,000 cps

- Pressure: Up to 300 PSIG

- Compliances: CSA, CE, ATEX, ASME

-

Heliflo Static Mixers

SERIES 1

Full 180 degree helices are used to provide mixing of fluids with viscosities up to 100,000 cps as in the production of plastics.

SERIES 2

Half Length 90 degree helices are used in low viscosity fluid mixing applications such as oil dispersion, color dilution, and coatings preparation.

SERIES 3

Highly efficient 45 degree helices are used in turbulent mixing applications such as water disinfection with chlorine and gas blending.

PAC

Shell and tube design for heat transfer in the production of plastics or a velocity increaser for dispersion. -

XCEL-FLO PLUS Mag-Drive & Sanitary Mixers

Sanitary Mixers

UET XCEL-FLO PLUS sanitary mixers are efficiently designed for CIP operations in pharmaceutical, food, bottling packaging, cosmetic, and dairy plants to improve productivity and lower costs. They are ideal in facilities wherever extreme moisture from cleaning or washdown is a concern, or where sanitary conditions are required. Also, in lieu of replacing the entire mixer, UET utilizes the same sanitary technology to upgrade existing mixers to “as new” sanitary standards to provide substantial operating and cost advantages.

FEATURES:

- Washdown inverter duty motors

- Food Grade lubricants

- FDA approved white epoxy finish on drive components

- Wetted parts are #4 polished, crevice-free stainless steel

- Impeller matched to the process requirements 2 Year Warranty

- Torques to 50,000 in-lb.

- Temperatures -100⁰C to 350⁰C

- Flange, Tri-clamp, or Threaded Connection

- Impellors for any process application

- Motors can be electric, variable speed, air or hydraulic

- Available with speed sensors, tachometers, and power monitors

- Available in most alloys, glass lining and coatings

- Several bearing designs to suit most conditions

- Stainless steel lubricated and shielded

- Hybrid ceramic/stainless dry running

- All ceramic dry running

- Sanitary features include:

- 15Ra Polish

- All Stainless drive

- Triclamp Ferrule®

- Pressures to 3000 PSI, including double wall

- Containment shells

- ATEX certified

-

Mixer Retrofit Capability

UET engineers solve your mixer problems using these retrofit components:

- High efficiency Hydrofoil impellers up to 216″ in diameter

- High torque shafting up to 50 feet in length

- Heavy duty gearboxes rated up to 1000 HP

- Mechanical seals designed to handle shaft runout up to 0.150″

- Variable speed motors

UET uses retrofit technology to upgrade existing mixers to current “best available technology”, Although most mixers are built to last twenty years or more, technological ADVANCE®s make them out of date and less cost effective within five years. There have been significant technical ADVANCE®s in impellers, electronics, seals, metallurgy, and gearboxes. An application that required a 10 HP mixer to operate efficiently twenty years ago may only need 3 HP in order to achieve the same results today.

UETS APPROACH TO RETROFITS

When a problem arises with a mixer it may only be necessary to address one component. If the turbine uses too much power, UET will retrofit the turbine. If the gearbox is worn out, UET will replace the gearbox. If the seal won’t stop leaking, UET will incorporate the correct seal design.

All UET retrofit equipment is guaranteed 100% for two years. Using this approach and utilizing the latest available technology, UET has successfully retrofitted mixers found in a wide range of industrial applications to “as new” condition. -

Impeller Types

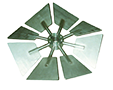

MB/A ADJUSTABLE PITCH IMPELLER

The extremely versatile MB/A mixing impeller features multiple configurations using 2 to 8 blades and in-field pitch adjustability to fine tune pumping and shear requirements.

Each blade can be individually pitched from 0 to 180 degrees.

The MB/A impeller can be easily adjusted in the field to handle a wide range of applications such as solids suspension, gas dispersion, viscous fluids, heat transfer, flocculation, and blending.

HYDROFOIL IMPELLER

The F4 Hydrofoil impeller provides approximately 200% more pumping capacity than a conventional 45 degree pitch impeller. This added mixing capacity is achieved without additional horsepower or the cost of additional mechanical equipment.