Anyone who wants to disperse, emulsify, homogenized, chill, dissolve, mix, neutralize, stir, circulate or exchange heat efficiently is faced with a demanding task ? from a technical and physical point of view. The mixing effect that flows develop depends on the shape of the container, the material and of course the type of mixer.

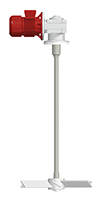

Due to the flexible modular system FLUX® is able to offer a wide range of options. This makes it possible to configure the mixer components of motor, shaft and mixing blade optimally for the application's requirements. If low speed is required slow running versions can be configured which are provided with intermediate gear and special mixing blades. The FLUX® mixers are available in various materials and with different mixing blades.

TECHNICAL DATA:

- Viscosity: max. 10.000 mPas*

- Circulating performance : max. 3.600 m3/h*

- Container sizes: 30 l to 30.000 l*

Item # |

Price |

Add To Cart/Request Quote |

|---|---|---|

| FLUX-Mixer-Fast FLUX-Mixer-Fast/Asset/FLUX-Mixer-Padle-Blades.png | QUOTE | Request Quote |

| FLUX-Mixer-Slow FLUX-Mixer-Slow/Asset/FLUX-Mixers-Agitators.png | QUOTE | Request Quote |